- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How do I choose a differential pressure transmitter?

2024-07-13 09:15:23

If you want your industrial processes to run smoothly and accurately, picking the right differential pressure transmitter is a crucial decision. It is essential to have an understanding of the primary characteristics that set these devices apart from the many others on the market. The Yokogawa EJA118E, a leading product known for its high performance and dependability, will be the focus of this blog's guidance on how to select the appropriate differential pressure transmitter. By resolving normal inquiries and contemplations, we intend to assist you with settling on an educated choice.

What Factors Should I Consider When Choosing a Differential Pressure Transmitter?

When selecting a differential pressure transmitter, several factors must be taken into account to ensure that the device meets your specific application requirements. The Yokogawa EJA118E is designed to address many of these considerations, making it a versatile and reliable choice for various industries.

Accuracy and Stability

Accuracy is paramount in pressure measurement. The Yokogawa EJA118E offers a high accuracy level, typically around ±0.065% of the span. This ensures precise measurements, which are crucial for maintaining process integrity, especially in applications such as chemical processing and pharmaceuticals where precision is critical.

Stability over time is another important aspect. The EJA118E provides excellent long-term stability, reducing the need for frequent recalibration and ensuring consistent performance.

Range and Span

The range and span of the transmitter determine the breadth of pressure measurements it can handle. The Yokogawa EJA118E is capable of measuring a wide range of differential pressures, making it suitable for various applications. Ensuring that the transmitter's range matches your system's requirements is vital for accurate and reliable measurements.

Environmental Conditions

Environmental conditions, including temperature, humidity, and exposure to corrosive substances, can significantly impact the performance of a differential pressure transmitter. The Yokogawa EJA118E is built to withstand harsh conditions, featuring robust construction and materials that ensure durability and reliable operation in challenging environments.

Communication Protocols

Modern industrial systems require seamless communication between devices. The Yokogawa EJA118E supports multiple communication protocols, such as HART, FOUNDATION Fieldbus, and BRAIN, allowing for easy integration into existing control systems and enhancing overall system efficiency.

Cost and Maintenance

While initial cost is a factor, it's important to consider the total cost of ownership, including maintenance and calibration. The Yokogawa EJA118E, with its high accuracy, long-term stability, and low maintenance needs, often results in lower overall costs over its lifespan.

How Does the Yokogawa EJA118E Stand Out in the Market?

The Yokogawa EJA118E is distinguished by its advanced features and reliability, making it a preferred choice for many industries. Here, we explore some of the key aspects that set this transmitter apart.

Advanced Sensing Technology

The EJA118E uses state-of-the-art sensing technology to provide accurate and stable measurements. Its silicon resonant sensor ensures high accuracy and stability, even in demanding conditions. This technology makes the EJA118E suitable for critical applications where precise measurements are essential.

Versatility and Flexibility

The EJA118E is designed to be versatile, capable of handling a wide range of applications from flow measurement to level detection. Its flexibility is enhanced by its ability to support various communication protocols, making it easy to integrate into different systems.

Robust Construction

Built to withstand harsh environmental conditions, the EJA118E features a robust design that ensures durability and longevity. This makes it an ideal choice for applications in industries such as oil and gas, chemical processing, and water treatment, where conditions can be particularly challenging.

User-Friendly Interface

The EJA118E comes with a user-friendly interface that simplifies installation, configuration, and maintenance. This ease of use reduces the time and effort required to set up and operate the transmitter, enhancing overall efficiency.

Comprehensive Diagnostics

The EJA118E includes advanced diagnostics that provide real-time data on the transmitter's performance. These diagnostics help in early detection of potential issues, allowing for proactive maintenance and minimizing downtime.

Why is Accuracy Important in Differential Pressure Measurement?

Accuracy in differential pressure measurement is crucial for several reasons, especially in industries where precision is key. The Yokogawa EJA118E offers high accuracy, making it suitable for a range of critical applications.

Ensuring Process Integrity

In processes where pressure differentials are used to control flow rates or levels, accurate measurements are essential to maintain process integrity. Any deviation can lead to inefficiencies, product quality issues, or even safety hazards. The high accuracy of the EJA118E ensures that these measurements are reliable and consistent.

Reducing Operational Costs

Accurate measurements help in optimizing processes, which can lead to significant cost savings. For example, in a chemical processing plant, precise control of pressure differentials can reduce waste, improve product yield, and lower energy consumption. The EJA118E's accuracy contributes to these efficiencies, resulting in lower operational costs.

Enhancing Safety

In many industrial applications, safety is directly linked to accurate pressure measurements. Incorrect readings can lead to dangerous situations, such as over-pressurization or equipment failure. The EJA118E's reliable measurements help prevent such incidents, ensuring a safer working environment.

How to Integrate the Yokogawa EJA118E into Your System?

Integrating the Yokogawa EJA118E into your system involves several steps to ensure optimal performance. Proper integration ensures that the transmitter provides accurate measurements and operates reliably within your specific application.

Assess Your System Requirements

Before integration, thoroughly assess your system's requirements, including the range of differential pressure measurements, environmental conditions, communication protocols, and accuracy needs. This assessment will help you determine the compatibility of the EJA118E with your system.

Plan the Installation

Carefully plan the installation process, considering factors such as the mounting location, wiring, and connection to other system components. Ensure that the installation site meets the environmental specifications of the EJA118E and allows for easy access for maintenance and calibration.

Configure the Transmitter

Proper configuration of the EJA118E is essential for accurate measurements. This includes setting the range and span, calibrating the transmitter, and configuring the communication protocols. Follow the manufacturer's guidelines for configuration to ensure optimal performance.

Test the System

After installation and configuration, conduct thorough testing to ensure that the EJA118E is operating correctly. Verify communication with other devices in your system and monitor real-time data to confirm accurate measurements.

Provide Training and Documentation

Training personnel on the operation and maintenance of the EJA118E is crucial for ensuring its long-term performance. Provide comprehensive training and documentation, including user manuals and technical specifications, to support ongoing operation and maintenance.

Regular Maintenance and Calibration

Schedule regular maintenance and calibration to maintain the accuracy and reliability of the EJA118E. Follow the manufacturer's recommendations for maintenance intervals and procedures to ensure the transmitter's continued performance.

What Are the Long-Term Benefits of Using the Yokogawa EJA118E?

Investing in a high-quality differential pressure transmitter like the Yokogawa EJA118E offers several long-term benefits that enhance overall system performance and efficiency.

High-Quality Materials and Construction

The EJA118E is constructed from high-quality materials that resist corrosion, extreme temperatures, and other harsh environmental conditions. This robust construction ensures durability and reduces the need for frequent replacements and maintenance.

Advanced Diagnostics

The EJA118E features advanced diagnostics and self-checking functions that provide real-time data on the transmitter's performance. These diagnostics allow for early detection of potential issues, enabling proactive maintenance and minimizing downtime.

Long-Term Stability

The EJA118E offers excellent long-term stability, which is crucial for maintaining accurate measurements over extended periods. This stability reduces the need for frequent recalibration and ensures consistent performance, resulting in cost savings and improved efficiency.

Comprehensive Support and Service

Yokogawa provides comprehensive support and service for the EJA118E, including technical assistance, calibration services, and spare parts availability. This support ensures that users can maintain and operate their transmitters effectively, maximizing their lifespan and performance.

Proven Track Record

The EJA118E has a proven track record of reliable performance in various industries. Its widespread use and positive feedback from users demonstrate its reliability and effectiveness in different applications. This proven track record gives users confidence in the transmitter's long-term performance.

Conclusion

Choosing the right differential pressure transmitter is crucial for ensuring the efficiency, safety, and reliability of your system. The Yokogawa EJA118E, with its high accuracy, robust construction, advanced sensing technology, and versatile communication options, stands out as an excellent choice for various industrial applications. By understanding your system's requirements and considering factors such as accuracy, range, environmental conditions, and maintenance needs, you can make an informed decision that will benefit your operations in the long term.

For more information on the Yokogawa EJA118E and other pressure measurement solutions, please contact us at lm@zyyinstrument.com.

References

"Differential Pressure Transmitters: An Overview," Process Instrumentation.

"How to Choose the Right Pressure Transmitter," Automation World.

"Yokogawa EJA118E Product Specifications," Yokogawa Official Website.

"Industrial Pressure Measurement Applications," Instrumentation Tools.

"Understanding Differential Pressure Transducers," Control Global.

"Advanced Sensing Technologies in Pressure Measurement," ISA.org.

"Flow Measurement Using Differential Pressure," Hydrocarbon Processing.

"Level Measurement Techniques," Chemical Engineering.

YOU MAY LIKE

Rosemount 3051GP pressure transmitter

Rosemount 2090P Pressure transmitter

Yokogawa EJA440E high-performance pressure transmitter

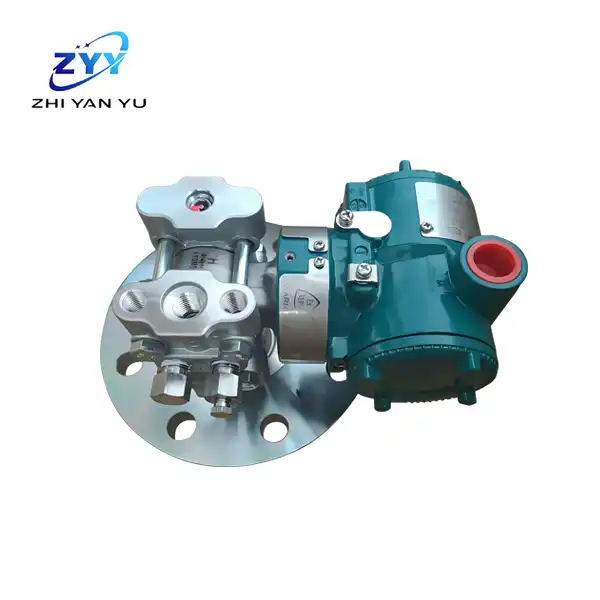

Yokogawa EJA210E flange-mounted differential pressure transmitter

E+H PMD75

Measurement: Operates by comparing pressures at these ports.

Use: Suitable for differential pressure applications.