- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Integration of pressure transmitters with control systems

2024-06-03 16:57:18

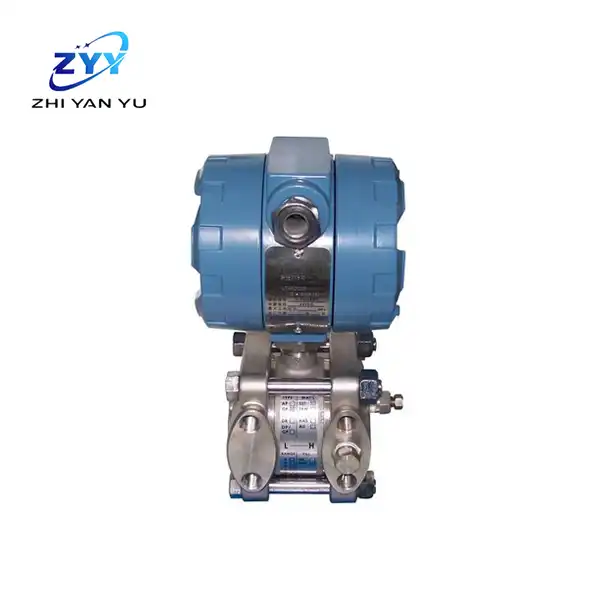

1. Understanding Pressure Transmitters

Rosemount 3051ca is essential instruments in industrial processes, providing accurate measurements of pressure levels in various applications. These devices play a crucial role in ensuring operational efficiency, safety, and quality control across industries such as oil and gas, manufacturing, pharmaceuticals, and more. A pressure transmitter typically consists of sensing elements, signal conditioning circuitry, and output electronics, all working together to convert pressure variations into electrical signals.

2. Importance of Integration

The seamless integration of Rosemount 3051ca with control systems holds paramount importance in the realm of industrial operations. This vital convergence facilitates real-time monitoring and management of critical process variables, laying the foundation for streamlined efficiency and enhanced productivity.

By establishing a cohesive connection between pressure transmitters and various control systems, including distributed control systems (DCS), programmable logic controllers (PLC), and supervisory control and data acquisition (SCADA) systems, operators are empowered with invaluable insights into the dynamics of industrial processes. This integration catalyzes automation, allowing for precise control and proactive measures, thereby mitigating the risk of operational disruptions and enhancing the overall reliability of the system.

Moreover, the integration of pressure transmitters with control systems paves the way for predictive maintenance strategies, enabling proactive and data-driven decision-making. This leads to a significant reduction in downtime. Potential issues can be identified and addressed before they escalate into critical failures.

3. Benefits of Integration

The seamless integration of Rosemount 3051ca with control systems presents a multitude of compelling advantages for industries on a global scale. Foremost, it empowers operators with the capability of remote monitoring and control, providing the ability to oversee pivotal processes from centralized control rooms or even through mobile devices. This enhanced accessibility and flexibility in monitoring operations results in heightened efficiency and responsiveness to dynamic operational needs.

Furthermore, the real-time data acquisition enabled by this integration fosters timely decision-making, thereby preempting potential equipment failures or process deviations. The instantaneous availability of critical operational data equips decision-makers with the insights needed to proactively address impending issues, ensuring the uninterrupted continuity of operations and bolstering operational reliability.

Moreover, the integration of pressure transmitters with control systems facilitates comprehensive data logging and analysis, laying the groundwork for robust and incisive process improvements. By harnessing the wealth of data generated through this integration, organizations can glean invaluable insights into operational trends and performance metrics, enabling informed decision-making and the implementation of targeted enhancements to optimize processes and drive continuous improvement.

4. Integration Techniques

Numerous sophisticated integration techniques are utilized to seamlessly integrate Rosemount 3051ca into control systems, ensuring optimal functionality and interoperability. One prevalent approach entails the direct connection of the transmitter's analog output signals, which commonly adhere to standardized ranges such as 4-20 mA or 0-10 V, to the analog input modules of control systems. This method facilitates the seamless transmission of sensor data to the control system, enabling real-time monitoring and precise control over critical parameters.

In addition to analog connectivity, digital communication protocols play a pivotal role in enhancing the integration process. Widely adopted protocols such as HART (Highway Addressable Remote Transducer) and Modbus facilitate bi-directional communication between pressure transmitters and control systems. These protocols empower control engineers with advanced diagnostic capabilities, allowing for proactive maintenance and troubleshooting of instrumentation.

Furthermore, the adoption of wireless communication technologies has emerged as a transformative integration strategy in recent years. WirelessHART, for instance, enables the seamless integration of pressure transmitters into control systems without the need for cumbersome wiring, thereby streamlining installation and maintenance processes while enhancing scalability and flexibility.

Moreover, the utilization of smart integration techniques, such as digital signal processing and advanced algorithms, enables the extraction of actionable insights from raw sensor data. By leveraging the computational capabilities of modern control systems, engineers can implement sophisticated control strategies and predictive maintenance routines, optimizing system performance and ensuring operational reliability.

5. Challenges and Solutions

The integration of pressure transmitters with control systems offers substantial benefits. Various challenges must be addressed to ensure seamless operation and system reliability. One of the primary hurdles encountered by industries is the compatibility issues stemming from the diverse range of devices manufactured by different suppliers. This can lead to interoperability issues and hinder the smooth communication between components, impeding the overall system performance.

Signal interference poses another significant challenge in the integration process, potentially resulting in data corruption or transmission errors. To overcome this obstacle, meticulous planning and shielding techniques are required to minimize electromagnetic interference and maintain signal integrity throughout the system.

Moreover, the escalating threat of cybersecurity breaches presents a critical concern for integrated control systems Industries become increasingly digitized. The risk of unauthorized access, data breaches, and cyber-attacks looms large. Robust cybersecurity measures such as implementing multi-layered defenses, conducting regular vulnerability assessments, and staying abreast of evolving cybersecurity threats are imperative to safeguarding sensitive data and maintaining system integrity.

In light of these challenges, proactive measures and innovative solutions are essential to overcoming obstacles in the integration of pressure transmitters with control systems. Collaborative efforts between manufacturers, integrators, and cybersecurity experts are crucial in developing resilient systems that can withstand the complexities of modern industrial environments. By embracing best practices, industry standards, and cutting-edge technologies, organizations can navigate these challenges successfully and unlock the full potential of integrated control systems in optimizing operational efficiency and enhancing productivity.

In conclusion, the integration of Rosemount 3051ca with control systems is indispensable for modern industrial processes, enabling enhanced monitoring, control, and optimization. By leveraging advanced integration techniques and addressing potential challenges, industries can harness the full potential of pressure transmitters to achieve operational excellence and maintain a competitive edge.

Contact Us:

For professional manufacturing solutions, contact us at lm@zyyinstrument.com. We are a GMP factory with a large inventory, complete certificates, and support OEM. Benefit from fast delivery, tight packaging, and testing support. Let's collaborate to elevate your industrial processes.

References:

- "Pressure Transmitters: Market Size, Share & Trends Analysis Report" - Grand View Research

- "Integration of Industrial Process Measurement and Control Devices" - ISA

- "HART Communication Protocol Specification" - HART Communication Foundation

- "Modbus Protocol Specification and Implementation Guide" - Modbus Organization

YOU MAY LIKE

Honeywell St800 Pressure Transmitter

Rosemount 1151ap Absolute Pressure Transmitter

Range ratio up to 50:1 supports 4-20mA and 1-5V HART

Gauge pressure/absolute pressure up to 4000psig/a

Wetted material: 316L SST, alloy C276

Basic diagnostic function certification: NSF, NACE

Lightweight and compact design

Yokogawa EJA130E high static pressure differential pressure transmitter

E+H PMD75

Measurement: Operates by comparing pressures at these ports.

Use: Suitable for differential pressure applications.

Yokogawa AXF electromagnetic flowmeter