- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Temperature transmitter accuracy verification methods

2024-06-28 16:10:28

Temperature Transmitter Accuracy Verification Methods

Introduction

In industrial processes where precise temperature control is paramount, Yokogawa Temperature Transmitter Yta613 play a crucial role. Temperature transmitter accuracy verification methods typically involve comparing the output of the transmitter to a reference standard or calibrated instrument. One common method is the ice bath or boiling water method, where the transmitter is exposed to known temperatures of ice and boiling water and its output compared to the expected values. Another method is using precision resistance thermometers or thermocouples in a stable temperature environment to validate the transmitter's readings. Additionally, comparison with traceable calibration equipment or software-based simulation can be employed for accurate verification of temperature transmitter performance.These devices convert temperature readings from sensors into electrical signals, which are then transmitted to control systems. However, ensuring the accuracy of these transmitters is vital for maintaining the efficiency and safety of operations. In this article, I will delve into various methods used to verify the accuracy of temperature transmitters, providing insights into their importance and application.

Calibration Standards

Calibration serves as the cornerstone for verifying the accuracy of yokogawa temperature transmitter. National and international standards, such as those set by organizations like the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI), provide guidelines for calibration procedures. These standards specify the calibration intervals, test methods, and acceptable tolerances, ensuring consistency and reliability across different industries.

Comparison with Reference Standards

One of the most common methods for verifying temperature transmitter accuracy is by comparing them with reference standards. These standards, often traceable to national metrology institutes, guarantee a high level of accuracy. This involves exposing the transmitter to known temperature conditions and comparing its output to the expected values provided by calibrated reference standards. Ice bath or boiling water methods are frequently used, where the transmitter's readings are compared to the temperatures of ice and boiling water. Additionally, precision resistance thermometers or calibrated thermocouples in stable environments can serve as reference standards. This method provides a direct assessment of the transmitter's accuracy and is essential for ensuring reliable temperature measurements in various industrial and scientific applications.

Sensor Simulation

Simulating temperature inputs is another effective method for verifying transmitter accuracy. This involves using a calibrated temperature source to generate specific temperature values and comparing the readings from the transmitter with the expected values. By simulating a range of temperatures, from ambient to extreme operating conditions, the performance of the transmitter across its entire operating range can be assessed. Simulating a Yokogawa Temperature Transmitter Yta613 sensor involves replicating its behavior and responses in various temperature conditions. This can be achieved using software programs or hardware-in-the-loop setups.

Software simulations involve creating algorithms that mimic the sensor's output based on temperature inputs. These simulations can account for factors like sensor calibration, response time, and accuracy.Hardware-in-the-loop simulations connect physical sensors to simulation software or test equipment. This allows for real-world testing of sensor behavior under controlled conditions, providing valuable data for analysis and calibration.Both methods help ensure the reliability and accuracy of temperature transmitter sensors in diverse applications.

Field Calibration Checks

In many industrial settings, temperature transmitters are subjected to harsh environments and operating conditions. Performing field calibration checks ensures that the transmitters continue to operate accurately in real-world conditions. This involves comparing the transmitter's output with known temperature references at various points within the process, allowing for adjustments to be made if deviations are detected.

Advanced Diagnostic Tools

Advancements in technology have led to the development of sophisticated diagnostic tools for verifying temperature transmitter accuracy. Advanced diagnostic tools for temperature transmitters include features like self-diagnostics, sensor drift detection, and sensor health monitoring. These tools utilize advanced algorithms to detect abnormalities in temperature readings, such as sensor degradation or wiring faults. Additionally, some temperature transmitters offer predictive maintenance capabilities by analyzing historical data to predict potential failures or calibration drift. Integration with asset management systems and communication protocols like HART or Foundation Fieldbus allows for remote monitoring and configuration. Overall, these advanced diagnostic tools enable proactive maintenance, minimize downtime, and ensure accurate temperature measurements in industrial processes. These tools, such as handheld communicators or digital multimeters with temperature measurement capabilities, provide real-time feedback on the transmitter's performance. Additionally, some transmitters are equipped with built-in self-diagnostic features that monitor internal parameters and alert operators to any potential issues.

Routine Maintenance

Ordinary support is fundamental for guaranteeing the drawn out exactness and unwavering quality of yokogawa temperature transmitter. This incorporates occasional investigation, cleaning, and recalibration according to the maker's suggestions. By sticking to an extensive upkeep plan, potential issues can be distinguished and tended to proactively, limiting the gamble of free time and exorbitant fixes. Some normal support undertakings include:

1. Calibration: Customary adjustment guarantees precision by contrasting the transmitter's result with a reference standard and making changes if fundamental.

2. Inspection: Occasionally examine the transmitter for any indications of harm, consumption, or wear. Clean the lodging and associations on a case by case basis to forestall pollution.

3. Testing: Perform functional tests to verify proper operation, including sensor response and signal output.

4. Seal Inspection: Check seals and gaskets for integrity to prevent ingress of moisture or contaminants.

5. Documentation: Keep records of maintenance activities, including calibration dates and results, for traceability and compliance with standards.

Conclusion

In conclusion, verifying the accuracy of Yokogawa Temperature Transmitter Yta613 is critical for ensuring the efficiency, safety, and compliance of industrial processes. By employing various methods such as calibration standards, comparison with reference standards, sensor simulation, field calibration checks, advanced diagnostic tools, and routine maintenance, operators can maintain the accuracy of temperature transmitters and mitigate the risk of errors. As technology continues to evolve, so too will the methods used to verify transmitter accuracy, ensuring the continued advancement of industrial processes.

Contact us

For professional-grade temperature transmitters and reliable accuracy verification methods, contact us today. We are a professional manufacturing supplier with a GMP factory, large inventory, and complete certificates. We support OEM orders, offer fast delivery, and provide tight packaging to ensure product integrity. Partner with us and gain access to our expertise and support for all your temperature measurement needs. Contact us at lm@zyyinstrument.com.

References

- International Organization for Standardization (ISO)

- American National Standards Institute (ANSI)

- National Metrology Institutes

- Manufacturer's Recommendations and Guidelines

- Industry Best Practices and Standards

YOU MAY LIKE

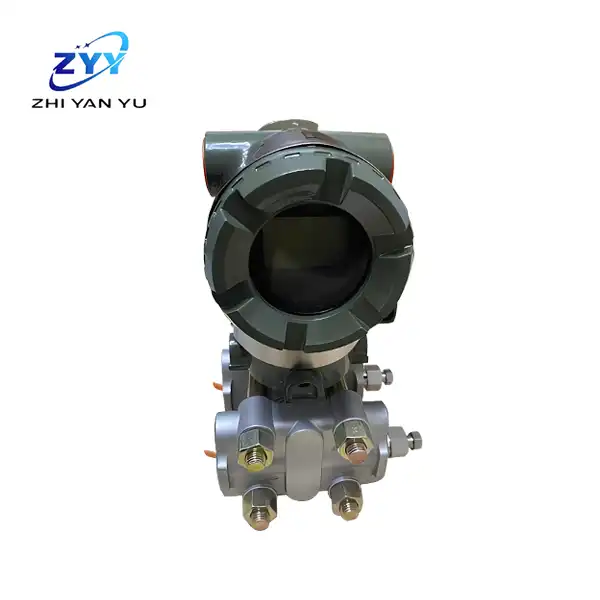

Rosemount ™ 3051TG direct connection pressure transmitter

Yokogawa EJX440A high-performance pressure transmitter

Siemens Pressure Transmitter 7MF4033/7MF4433

Model: 7MF/7ML/7ME/7NG/7MH/7MB/7KG/7KM

Output signal type: 4-20mA or 0-10V

4-20mA signal advantages: suppress electromagnetic interference, easy to use

Application industries: chemical industry, petrochemical, food, pharmaceutical, aerospace, shipbuilding

Advantages: high precision, good stability, strong anti-interference ability, easy installation and maintenance

Yokogawa EJX130A high static pressure differential pressure transmitter

Siemens valve positioner 6DR5020-0NG00-0AA0