- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Temperature transmitter selection criteria for harsh environments

2024-06-11 16:51:13

Title: Temperature Transmitter Selection Criteria for Harsh Environments

As a designer entrusted with choosing temperature transmitters for modern applications, I comprehend the basic job these gadgets play in guaranteeing functional effectiveness and security, especially in cruel conditions. From compound handling plants to petroleum processing plants and power age offices, the requirement for dependable temperature estimation in outrageous circumstances couldn't possibly be more significant. In this thorough aide, I'll dive into the fundamental models for choosing temperature transmitters custom fitted to endure the afflictions of testing working conditions.

Understanding the Importance of Temperature Transmitters in Industrial Settings

Temperature transmitters act as imperative instruments in observing and controlling temperature varieties inside modern cycles. Whether it's keeping up with ideal circumstances for synthetic responses, guaranteeing hardware works inside safe temperature restricts, or working with proficient energy the board,Rosemount 3144p assume a significant part. In conditions where factors like high temperatures, destructive synthetic substances, or mechanical vibrations are pervasive, picking the right temperature transmitter becomes fundamental to functional achievement and life span of hardware. Temperature transmitters assume a critical part in modern settings, giving exact and dependable estimations of temperature in different cycles. These gadgets are fundamental for keeping up with ideal circumstances, guaranteeing item quality, and defending hardware and staff.

One key importance of temperature transmitters is their ability to accurately monitor temperature levels in real-time. In industrial processes, maintaining precise temperature control is vital for ensuring product quality and consistency. Temperature transmitters enable operators to closely monitor temperature variations and make timely adjustments to maintain desired conditions.

Moreover, temperature transmitters contribute to the overall efficiency and productivity of industrial operations. By providing continuous temperature monitoring, these devices help prevent equipment malfunctions and process deviations that can lead to costly downtime and production delays. They also facilitate predictive maintenance strategies by detecting potential issues before they escalate into major problems, thereby reducing the risk of equipment failures and optimizing uptime.

Key Factors to Consider When Selecting Temperature Transmitters for Harsh Environments

In brutal conditions, Rosemount 3144p should show powerful development and versatility to endure unfavorable circumstances without compromising exactness or dependability. While assessing temperature transmitters, a few key elements become an integral factor, including:

- Nook Insurance: Selecting temperature transmitters with walled in areas appraised for entrance assurance (IP) against residue and water entrance is fundamental. Moreover, choosing models with ruggedized nooks fit for enduring effect and natural stressors guarantees long haul sturdiness.

- Temperature Reach: Consider the full working temperature scope of the application and pick temperature transmitters prepared to do precisely estimating temperatures inside this range. Transmitters with wide temperature ranges offer adaptability in assorted modern settings.

-

Chemical Compatibility: Assess the compatibility of temperature transmitter materials with chemicals present in the operating environment to mitigate corrosion or degradation over time. Stainless steel or exotic alloys are often preferred for their resistance to corrosive substances.

-

Vibration and Shock Resistance: In environments characterized by machinery vibrations or mechanical impacts, selecting temperature transmitters with robust shock and vibration resistance prevents signal disruptions and ensures consistent performance.

-

Electromagnetic Interference (EMI) Protection: Industrial environments may generate electromagnetic interference, which can affect the accuracy of temperature measurements. Choosing transmitters with adequate EMI protection safeguards against signal distortion and ensures reliable data transmission.

Exploring the Role of Environmental Conditions in Temperature Transmitter Performance

The environmental conditions surrounding rosemount 3144p temperature transmitter significantly influence their performance and longevity. Factors such as temperature extremes, humidity levels, exposure to corrosive substances, and mechanical stressors can impact transmitter reliability and accuracy. To mitigate these effects, it's crucial to assess the specific environmental challenges present in the operating environment and select temperature transmitters designed to withstand these conditions effectively. The performance of temperature transmitters is intricately linked to environmental conditions, as these factors can significantly influence their accuracy and reliability. Environmental conditions such as temperature, humidity, pressure, and vibration can all impact the functionality of temperature transmitters.

Temperature, for example, straightforwardly influences the exhibition of temperature sensors inside the transmitter. Outrageous temperatures can present mistakes in readings or even harm the actual sensors. Essentially, dampness levels can cause buildup, influencing the electrical parts and possibly prompting glitches.

Pressure varieties, particularly in modern settings, can apply mechanical weight on the transmitter, possibly influencing its alignment and exactness. Vibration from neighboring hardware or gear can likewise upset delicate parts inside the transmitter, prompting mistakes in temperature readings.

Moreover, environmental conditions can also impact the overall lifespan of temperature transmitters. Exposure to harsh conditions over an extended period can lead to premature wear and tear, necessitating more frequent maintenance or replacement.

Evaluating Calibration and Accuracy in Temperature Transmitter Selection

Adjustment and exactness are vital contemplations while choosing rosemount 3144p temperature transmitter for modern applications. Exact temperature estimation is fundamental for process control, quality affirmation, and administrative consistence. Before arrangement, temperature transmitters ought to go through thorough adjustment to guarantee accuracy across the working reach. Moreover, choosing transmitters with worked in diagnostics and programmed self-alignment highlights keeps up with precision over the long run, decreasing the requirement for manual mediation and limiting margin time.

Case Studies: Real-World Applications of Temperature Transmitters in Extreme Conditions

To illustrate the practical application of Rosemount 3144p in harsh environments, let's explore a few real-world scenarios:

-

Chemical Processing Plant: In a chemical processing plant where corrosive substances are present, temperature transmitters with corrosion-resistant materials and robust enclosures are essential. These transmitters accurately monitor temperature fluctuations, ensuring optimal process conditions and safeguarding equipment integrity.

-

Oil Refinery: In an oil refinery where high temperatures and flammable gases pose significant risks, temperature transmitters equipped with explosion-proof housings and intrinsically safe designs are critical. These transmitters provide accurate temperature measurements without compromising safety in hazardous environments.

-

Power Age Office: In a power age office presented to outrageous temperatures and mechanical vibrations, temperature transmitters with vibration-safe development and wide temperature ranges are crucial. These transmitters empower exact temperature observing, adding to productive activity and hardware unwavering quality.

By choosing temperature transmitters customized to the one of a kind difficulties of every climate, modern offices can streamline execution, improve security, and drag out hardware life expectancy.

Contact us: For professional manufacturing, GMP factory standards, extensive inventory, complete certifications, OEM support, fast delivery, secure packaging, and testing support, contact us at lm@zyyinstrument.com.

References:

- "Temperature Transmitters for Industrial Applications." Omega Engineering, www.omega.com/en-us/resources/temperature-transmitters-industrial-applications.

- "Selecting the Right Temperature Transmitter for Your Application." Emerson, www.emerson.com/en-us/automation/temperature-transmitter.

- "Temperature Transmitters: Selecting the Right Device for Your Application." Yokogawa, www.yokogawa.com/us/library/resources/application-notes/temperature-transmitters-selecting-the-right-device-for-your-application/.

YOU MAY LIKE

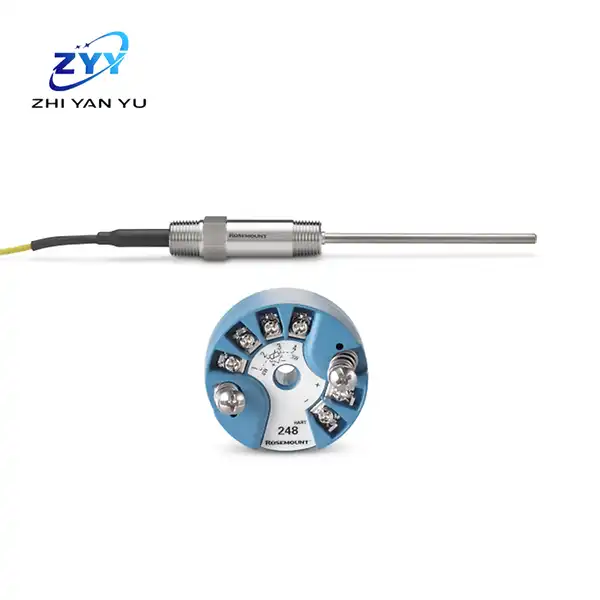

Rosemount ™ 214C thermal resistance temperature sensor

Rosemount 3051TA Absolute Pressure Transmitter

Yokogawa EJA530E pressure transmitter

E&H Pmd76 Differential Pressure Transmitter

View More

Rosemount 8732E field mounted electromagnetic flowmeter transmitter