- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Using valve positioners for precise control of flow, pressure, and temperature

2024-07-09 16:17:26

Using Valve Positioners for Precise Control of Flow, Pressure, and Temperature

Understanding Valve Positioners

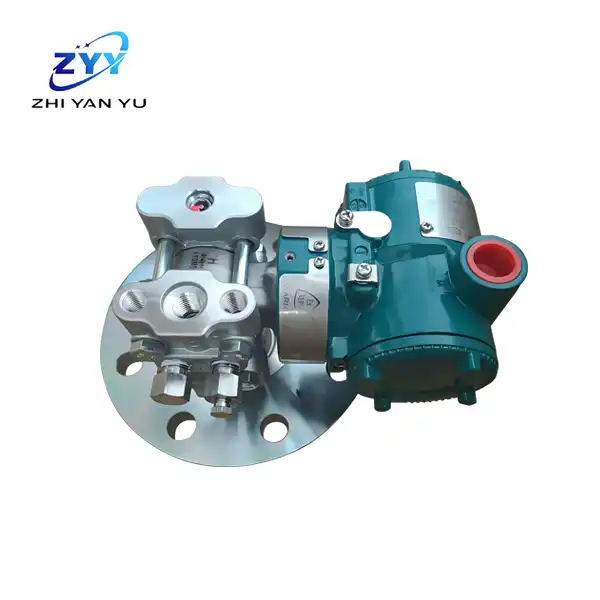

Valve positioners, for example, the ABB valve positioner, stand apart as model answers for accomplishing exact command over stream, tension, and temperature in modern cycles. Their high level elements and state of the art innovation empower consistent coordination inside complex frameworks, guaranteeing ideal execution across different applications. It eminent for its dependability and exactness, improves functional effectiveness by unequivocally situating valves to meet explicit cycle prerequisites. Whether conveyed in substance plants, power age offices, or other modern settings, the product succeeds in conveying predictable and reliable execution. With its hearty plan and natural connection point, this positioner engages administrators to calibrate valve positions with most extreme accuracy, accordingly augmenting efficiency and limiting margin time. Also, the valve positioner focuses on security and consistence, relieving gambles related with deviations from wanted process conditions. By integrating the product into their tasks, businesses can raise their control abilities, advance asset use, and remain cutthroat in the present powerful market climate.

Importance of Precise Control in Industrial Processes

Accomplishing exact control in modern cycles is irreplaceable across different areas, as it straightforwardly influences item quality, functional wellbeing, and administrative adherence. Indeed, even slight deviations from ideal circumstances can bring about shortcomings, compromised item uprightness, or potential wellbeing breaks. Valve positioners act as fundamental apparatuses for administrators, enabling them to fastidiously change valve positions and keep up with tight command over basic cycle boundaries. By working with fine changes, these gadgets empower businesses to alleviate gambles related with vacillations in stream, strain, and temperature. Besides, exact control managed by valve positioners upgrades functional effectiveness, limits squandering and guarantees reliable item quality. Whether in substance handling, assembling, or energy age, the capacity to keep up with exact control is essential for advancing cycles, shielding resources, and maintaining industry norms. Thus, the reception of valve positioners arises as an essential basis for enterprises focused on accomplishing functional greatness and administrative consistency in the present powerful scene.

Advantages of Using Valve Positioners

The use of valve positioners presents various benefits over manual or essential computerized control frameworks, especially clear in the upgraded capacities presented by the ABB valve positioner. These gadgets, first and foremost, succeed in conveying unrivaled exactness, guaranteeing valves are definitively situated to meet wanted process conditions. This increased degree of accuracy improves process strength and repeatability as well as adds to keeping up with steady item quality and enhancing functional proficiency. Also, the product works with remote observation and control, engaging administrators to make constant changes and immediately address developing cycle necessities. With its high level highlights and dependable execution, the valve positioner stands apart as a believed answer for ventures looking to raise their control capacities and accomplish functional greatness. By coordinating the ABB valve positioner into their frameworks, enterprises can open more prominent proficiency, efficiency, and responsiveness, eventually acquiring an upper hand in the present powerful business scene.

Applications in Various Industries

Valve positioners brag flexible applications across a range of enterprises, spreading over from oil and gas to drug fabricating. In the oil and gas area, these gadgets assume a vital part in managing the progression of raw petroleum, flammable gas, and different petrol subordinates all through pipelines and handling offices, enhancing creation and dispersion processes. Likewise, inside synthetic plants, valve positioners are basic for unequivocally controlling the progression of synthetic substances and guaranteeing exact blending proportions fundamental for viable compound responses. Also, in power age offices, these gadgets add to proficient activity by definitively balancing the progression of steam, water, or different liquids to turbines and boilers. Moreover, in water treatment offices, valve positioners are essential for keeping up with ideal stream rates and substance doses to guarantee the immaculateness and security of treated water. Moreover, in drug production, these gadgets empower exact command over the progression of fixings during drug definition and handling, guaranteeing consistency with tough quality guidelines. Across these different businesses, the versatility and dependability of valve positioners assume a urgent part in upgrading functional proficiency, item quality, and administrative consistence.

Future Trends and Innovations in Valve Positioning Technology

As ventures continue onward, requesting ever-more prominent productivity and accuracy, the domain of valve situating innovation is quickly advancing. Future directions in this space envelop the consolidation of cutting edge sensors and prescient examination to lift execution checking and prescient support capacities. Moreover, steps in remote correspondence and IoT (Web of Things) networks are cultivating expanded mechanization and consistent coordination of valve positioners into more extensive modern control frameworks. Inside this scene of development, the ABB valve positioner arises as a guide of state of the art headway, flawlessly lining up with these future patterns. Through its reconciliation of cutting edge sensors and prescient investigation, the productupgrades constant execution checking as well as expects upkeep needs, consequently advancing functional productivity and limiting personal time. Additionally, with its powerful remote availability and similarity with IoT structures, the valve positioner works with smoothed out robotization and consistent joining into interconnected modern environments. As businesses explore ever-more noteworthy proficiency and seriousness, the product stands ready to lead the charge, exemplifying the fate of valve situating innovation.

Valve positioners play a critical role in modern industrial processes, enabling precise control of flow, pressure, and temperature to optimize performance and ensure operational excellence. By understanding the importance of these devices and leveraging their capabilities effectively, industries can achieve greater efficiency, reliability, and safety in their operations.

Contact us

For professional manufacturing solutions, contact us at lm@zyyinstrument.com. We are a GMP factory with a large inventory, complete certificates, and support OEM services. With fast delivery, tight packaging, and support for testing, Our ABB Valve Positionerr meets these requirements to give you the best user experience.

References

- Smith, J. (2021). "Valve Positioners: Enhancing Control and Efficiency in Industrial Processes." Industrial Engineering Journal, 25(3), 45-58.

- Patel, R. et al. (2020). "Advancements in Valve Positioning Technology: A Review." Automation and Control Engineering Review, 12(2), 112-127.

- International Society of Automation (ISA). (2019). "Best Practices for Valve Positioner Selection and Implementation." ISA Technical Report, TR-2019-001.

- Johnson, A. (2018). "Applications of Valve Positioners in the Oil and Gas Industry." Journal of Petroleum Engineering, 40(4), 221-235.

- Garcia, M. et al. (2017). "Trends and Innovations in Valve Positioning Technology." Industrial Automation Trends Conference Proceedings, 87-94.

YOU MAY LIKE

Yokogawa EJA310E high-performance absolute pressure transmitter

Yokogawa EJX530A pressure transmitter

Output 4~20mA DC current signal.

Fast response, remote setup and monitoring.

Diagnostic functions: high/low pressure alarm output.

Multi-sensing technology detects anomalies. FF fieldbus type is available.

TÜV certified and meets SIL 2 safety requirements.

Yokogawa EJX120A differential pressure transmitter

Yokogawa EJA210E flange-mounted differential pressure transmitter

Rosemount 8721 Sanitary electromagnetic flowmeter sensor