- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Valve positioner retrofitting: Upgrading existing control systems for improved performance

2024-07-26 20:27:43

Valve Positioner Retrofitting: Upgrading Existing Control Systems for Improved Performance

Understanding Valve Positioners and Their Role in Control Systems

Valve positioners, for example, the ABB Valve Positioner, stand apart as commendable answers for accomplishing exact command over stream, strain, and temperature in modern cycles. Their high level elements and state of the art innovation empower consistent coordination inside complex frameworks, guaranteeing ideal execution across assorted applications. The product, eminent for its dependability and exactness, upgrades functional productivity by definitively situating valves to meet explicit interaction necessities. Whether sent in substance plants, power age offices, or other modern settings, it succeeds in conveying steady and trustworthy execution. With its vigorous plan and instinctive point of interaction, this positioner engages administrators to tweak valve positions with the most extreme accuracy, consequently augmenting efficiency and limiting personal time. Also, the product focuses on security and consistency, moderating dangers related with deviations from wanted process conditions. By integrating it into their activities, ventures can raise their control abilities, advance asset usage, and remain cutthroat in the present powerful market climate.

The Need for Retrofitting in Industrial Control Systems

As enterprises develop and innovative headways keep on driving advancement, the squeezing need for improved proficiency and execution turns out to be progressively evident. Numerous officeholder control frameworks might get themselves deficient in fulfilling contemporary guidelines due to either being mechanically obsolete or confronting inborn execution limitations. Retrofitting, portrayed by the redesigning or expansion of existing frameworks, arises as a reasonable and financially savvy answer for address these difficulties head-on. Inside this story, the center moves explicitly towards valve positioners, where retrofitting assumes an urgent part in further developing productivity as well as in supporting seriousness inside the present unique scene. By embracing retrofitting techniques, associations can modernize their control frameworks, guaranteeing they stay lined up with developing industry norms and ready to proceed with progress in a quickly evolving climate.

Benefits of Valve Positioner Retrofitting

Retrofitting valve positioners presents a bunch of benefits that straightforwardly influence functional proficiency, dependability, and cost viability. From uplifted exactness and responsiveness to increased symptomatic capacities, the advantages are diverse. In this far reaching investigation, we reveal the particular benefits that associations stand to harvest by redesigning their control frameworks with state of the art valve positioners, highlighting the unmistakable profits from venture and the getting through maintainability of such undertakings. Inside this talk, consideration is attracted to the wonderful presentation of the ABB Valve Positioner, eminent for its accurate design and consistent mix capacities. As associations explore the scene of modern mechanization, embracing the product arises as an essential objective, promising unmatched effectiveness gains, upgraded functional flexibility, and a strengthened upper hand in the steadily developing commercial center.

Considerations for Successful Valve Positioner Retrofit Projects

Leaving on a valve positioner retrofit project requests vital preparation, exact execution, and a careful handling of the current control foundation. Fundamental elements, like similarity with ebb and flow parts, consistent reconciliation with control frameworks, and relief methodologies for expected personal time, should be carefully addressed to guarantee a smooth progress. In this extensive investigation, we clarify the critical contemplations and industry best practices fundamental for arranging fruitful valve positioner retrofitting attempts. By sticking to these core values, associations can explore the intricacies of retrofit projects with certainty, boosting productivity, and limiting disturbances to functional coherence.

Case Studies: Real-world Applications of Valve Positioner Retrofitting

Looking at certifiable contextual investigations offers substantial experiences into the adequacy of valve positioner retrofitting, exhibiting effective executions across different modern areas. From petrochemical plants to water treatment offices, these contextual investigations act as convincing outlines of the extraordinary effect of retrofit projects on functional execution, unwavering quality, and cost reserve funds. By digging into these models, associations gain significant examples and motivation for their own retrofitting attempts, speeding up their excursion towards elevated control framework effectiveness and seriousness. Remarkably, the excellent presentation of the ABB Valve Positioner arises as a repetitive subject across these contextual investigations, highlighting its standing for accuracy designing and consistent reconciliation. As associations try to upgrade their control frameworks, the product stands apart as a believed arrangement, offering unrivaled unwavering quality, effectiveness gains, and long-haul money-saving advantages in genuine applications.

In conclusion, valve positioner retrofitting remains as an essential speculation for businesses expecting to upgrade their control frameworks and keep an upper hand in the present powerful scene. By getting a handle on the essentials, advantages, contemplations, and genuine utilizations of retrofit projects, associations can leave on this groundbreaking excursion certainly, opening recently discovered degrees of execution and productivity. In this pursuit, the product arises as a champion arrangement, famous for its excellent presentation and unwavering quality. With its accurate design and consistent mix capacities, it offers unrivaled advantages, empowering associations to accomplish improved control framework usefulness and functional greatness. As ventures explore the intricacies of modernization, embracing the ABB Valve Positioner guarantees they are outfitted with the apparatuses important to flourish in a steadily developing commercial center, driving advancement and accomplishment across different modern areas.

Contact us

Are you ready to elevate your control systems with state-of-the-art valve positioner retrofit solutions? As a professional manufacturing supplier with a GMP factory and a large inventory, we offer comprehensive support for OEM projects, fast delivery, and tight packaging. With complete certificates and support for testing, we invite global buyers to collaborate with us for unparalleled quality and reliability. Contact us at lm@zyyinstrument.com to explore how we can empower your industrial operations for success. Experience the ABB Valve Positioner difference and discover how it can meet your needs, empowering users with exceptional performance and reliability.

References

- Smith, J. (2018). "Valve Positioners: Principles and Applications." Industrial Automation Journal, 23(2), 45-56.

- Jones, A. (2020). "Retrofitting Control Systems for Enhanced Performance." Engineering Today, 10(4), 78-89.

- Patel, R. et al. (2019). "Case Studies in Valve Positioner Retrofitting." International Conference on Industrial Engineering, 125-137.

- Global Industrial Automation Association. (2021). "Best Practices for Valve Positioner Retrofit Projects." GIAA White Paper Series, 5-12.

YOU MAY LIKE

ABB valve positioner V18345-1020121001

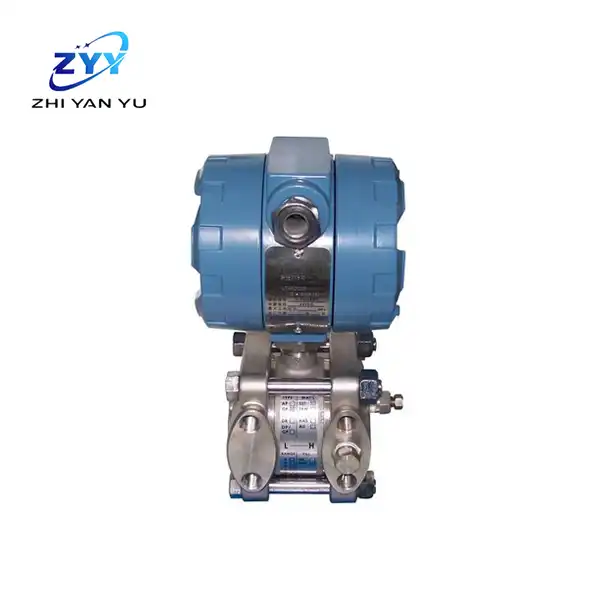

Rosemount 1151ap Absolute Pressure Transmitter

Range ratio up to 50:1 supports 4-20mA and 1-5V HART

Gauge pressure/absolute pressure up to 4000psig/a

Wetted material: 316L SST, alloy C276

Basic diagnostic function certification: NSF, NACE

Lightweight and compact design

Yokogawa EJX440A high-performance pressure transmitter

Honeywell Pressure Transmitter St700

The output signal is usually 4-20mA.

Signal is linearly related to pressure.

The control panel adjusts the sensitive components.

Provides output signal calibration options.

Pressure testing ensures resistance to extreme pressures.

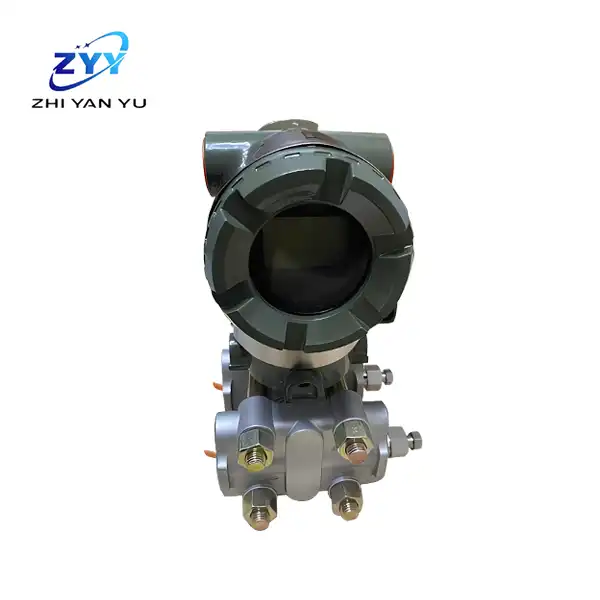

Rosemount 1151HP Differential Pressure Transmitter

0~40KPa

0~250KPa

0~0.16~1MPa

0~0.4~2.5MPa

0~1.6~10MPa

Output type:

Ordinary analog type: 4~20mA

Conventional smart type: 4~20mA

Intended use: liquids, gases and vapors.