- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Importance of fail-safe features in valve positioners for critical processes

2024-07-15 14:40:09

1. Understanding the Role of Valve Positioners in Critical Processes

In industries characterized by critical operations like oil and gas refining, chemical manufacturing, and power generation, the meticulous management of valves is indispensable. Azbil Smart Valve Positioner assume a pivotal function in guaranteeing the precise and dependable operation of valves, overseeing the movement of fluids or gases. Operating based on input signals usually sourced from control systems or sensors, a valve positioner essentially dictates the positioning of the valve actuator. This exacting control is fundamental in upholding optimal process conditions, averting mishaps, and facilitating efficient performance. Nevertheless, within critical processes, any malfunction in valve positioners could lead to grave repercussions, underscoring the necessity of integrating fail-safe features to safeguard against potential risks.

2. The Potential Risks of Valve Positioner Failures

Ensuring the reliability of Azbil smart valve positioner in critical processes is paramount, as any malfunction could have far-reaching consequences. The industrial sector, particularly in fields such as oil and gas, chemical manufacturing, and power generation, faces significant risks when it comes to valve positioner failures. These risks encompass not only operational disruptions and safety hazards, but also extend to potential environmental damage and substantial financial losses.

In the oil and gas industry, a faulty valve positioner has the potential to cause the release of hazardous substances, which can lead to catastrophic events such as fires, explosions, and the dissemination of toxic materials. Similarly, within chemical manufacturing plants, an improperly functioning valve could result in the unintended mixing of incompatible chemicals, creating the possibility of chemical reactions, spills, or uncontrolled chain reactions. Moreover, in power generation facilities, a malfunctioning valve positioner could disrupt electricity supply, causing downtime and consequent revenue loss.

The ramifications of these failures underscore the critical importance of implementing fail-safe features in valve positioners for critical processes. By minimizing the likelihood of such failures, industries can uphold the safety, dependability, and productivity of their operations. Additionally, the integration of advanced fail-safe mechanisms not only mitigates operational risks but also serves as a proactive measure to safeguard against potential environmental harm and financial repercussions. Therefore, prioritizing the implementation of fail-safe features in valve positioners is essential in maintaining the integrity and resilience of critical processes.

3. Key Fail-Safe Features in Valve Positioners

Ensuring the reliability and safety of Azbil Smart Valve Positioners in critical processes is of paramount importance, and modern valve positioners are equipped with a range of fail-safe features to address these concerns. These features are specifically engineered to identify faults or abnormal conditions and initiate appropriate measures to prevent or mitigate any adverse consequences. Among the key fail-safe features, redundancy plays a vital role, encompassing the replication of critical components or subsystems to ensure uninterrupted operation in the event of a failure. This redundancy can involve duplicating sensors, actuators, or control circuits to provide backup functionality in the event of a primary component failure. Furthermore, the inclusion of self-diagnostic capabilities enables valve positioners to continuously monitor their own performance, promptly identifying potential issues before they escalate into critical failures. In addition to redundancy and self-diagnostic capabilities, other fail-safe features such as fault-tolerant design, automatic shutdown mechanisms, and emergency override functions also contribute significantly to the overall reliability and safety of valve positioners in critical processes. These fail-safe features collectively serve to significantly reduce the risk of valve positioner failures and enhance the overall operational security in critical industrial applications.

4. The Role of Fail-Safe Features in Ensuring Compliance and Reliability

The incorporation of fail-safe features in Azbil smart valve positioner holds significant implications beyond enhancing safety and risk mitigation. These features, essential for ensuring compliance with industry regulations and standards, are mandated by various regulatory bodies such as the Occupational Safety and Health Administration (OSHA), the Environmental Protection Agency (EPA), and the International Organization for Standardization (ISO). The stringent requirements outlined by these entities encompass the design, operation, and maintenance of industrial processes, emphasizing the imperative nature of fail-safe systems.

By integrating fail-safe features into valve positioners, manufacturers can assert their unwavering commitment to regulatory adherence, thereby preemptively avoiding potential fines, penalties, or legal liabilities. Moreover, the implementation of these features serves to bolster the overall reliability and uptime of critical processes, effectively minimizing unplanned downtime and maximizing productivity and profitability. This multifaceted impact underscores the pivotal role that fail-safe features play in upholding operational excellence and regulatory compliance within industrial settings, positioning them as indispensable components of responsible and sustainable operations.

Furthermore, the proactive integration of fail-safe mechanisms aligns with the industry's relentless pursuit of safety, quality, and environmental responsibility. These features not only mitigate risks but also demonstrate a proactive approach to meeting and surpassing regulatory expectations, thereby reinforcing the industry's dedication to operational excellence and responsible practices.

5. Selecting the Right Valve Positioner with Fail-Safe Features

When it comes to the selection of Azbil Smart Valve Positioner for critical processes, careful consideration of the specific application requirements and equipment reliability is paramount. Factors requiring attention encompass the nature of the process fluid or gas, operational conditions (such as temperature, pressure, and flow rates), environmental elements (such as corrosive or hazardous atmospheres), and regulatory standards. Moreover, a thorough assessment of the fail-safe attributes of various valve positioner models is essential. This is to guarantee comprehensive protection against potential failures.

Key features to look for include redundant components, self-diagnostic capabilities, fault-tolerant design, and emergency shutdown functions. Additionally, the reputation and track record of the manufacturer, as well as the availability of technical support, spare parts, and maintenance services, should be carefully considered.By opting for the appropriate valve positioner equipped with robust fail-safe features, it is possible to minimize risks, ensure adherence to regulations, and uphold the reliability of critical processes.

Contact us

For reliable valve positioners with advanced fail-safe features, trust our expertise. As a professional manufacturing supplier, we offer GMP factory-certified products with a large inventory and complete certificates. We support OEM customization, fast delivery, and tight packaging to meet your specific needs. Contact us at lm@zyyinstrument.com to learn more about how we can support your critical processes and ensure the safety and efficiency of your operations.

References:

- American Petroleum Institute (API) Standards.

- International Organization for Standardization (ISO) 15848.

- Occupational Safety and Health Administration (OSHA) Regulations.

- Environmental Protection Agency (EPA) Guidelines.

- Valve Manufacturers Association of America (VMA) Standards.

YOU MAY LIKE

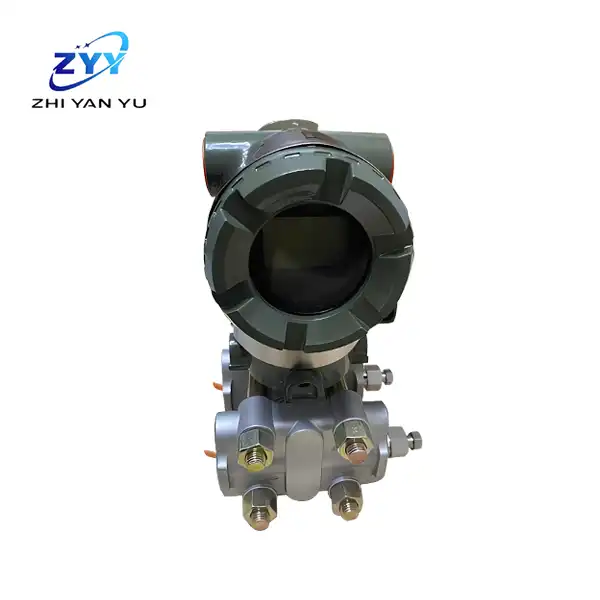

Rosemount ™ 2051TA Direct Connection Absolute Pressure Transmitter

Yokogawa EJA430E high-performance pressure transmitter

Yokogawa EJA440E high-performance pressure transmitter

Yokogawa EJX440A high-performance pressure transmitter

Rosemount 1151HP Differential Pressure Transmitter

0~40KPa

0~250KPa

0~0.16~1MPa

0~0.4~2.5MPa

0~1.6~10MPa

Output type:

Ordinary analog type: 4~20mA

Conventional smart type: 4~20mA

Intended use: liquids, gases and vapors.