- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Integration of temperature transmitters with control systems

2024-06-11 17:00:11

Understanding Temperature Transmitters and Control Systems

In comprehending the intricate dynamics of Yokogawa Temperature Transmitter Yta610 and control systems, one must first grasp the fundamental principles underlying their functionality. Temperature transmitters serve as pivotal instruments in the realm of process control, tasked with the crucial role of accurately measuring temperature fluctuations within industrial settings. These sophisticated devices operate by sensing temperature variations and converting them into standardized signals, typically ranging between 4 to 20 mA, facilitating seamless transmission to interconnected control systems.

Conversely, control systems serve as the nerve center of industrial operations, orchestrating a symphony of parameters to maintain optimal efficiency and productivity. These intricate systems wield formidable capabilities, encompassing a spectrum of functions such as regulation, monitoring, and automation. Through intricate algorithms and real-time data analysis, control systems dynamically adjust variables to uphold desired temperature levels and mitigate deviations, ensuring stringent adherence to operational parameters.

The integration of temperature transmitters with control systems heralds a new era of precision and efficacy in industrial processes. By seamlessly amalgamating these technologies, organizations can harness actionable insights and exert unparalleled command over their operational landscape. However, navigating the complexities inherent in this integration journey demands meticulous planning, robust infrastructure, and unwavering commitment to excellence.

Benefits of Integrating Temperature Transmitters with Control Systems

Incorporating yokogawa temperature transmitter into control systems yields a plethora of advantages for industrial enterprises. Primarily, this integration empowers real-time monitoring of temperature parameters, enabling proactive maintenance measures and preempting potential equipment malfunctions that could lead to disruptive downtime. Furthermore, the amalgamation of these systems facilitates granular temperature regulation, fostering heightened product quality and consistency across production lines.

Beyond bolstering quality control measures, the convergence of temperature transmitters and control systems drives operational efficiency through streamlined processes. By automating temperature monitoring and control tasks, organizations can curtail labor expenditures and allocate resources more strategically, amplifying overall productivity. Moreover, the seamless synchronization of these technologies equips businesses with actionable insights into temperature fluctuations, empowering informed decision-making and facilitating agile responses to evolving operational demands.

Another notable benefit of this integration lies in its capacity to enhance regulatory compliance efforts. With integrated systems in place, businesses can ensure adherence to stringent industry standards and regulatory requirements governing temperature-sensitive processes. By maintaining optimal temperature conditions within predefined parameters, organizations can mitigate compliance risks and safeguard against potential fines or penalties.

Factors to Consider When Integrating Temperature Transmitters

When considering the integration of yokogawa temperature transmitter with control systems, it is essential to thoroughly evaluate several critical factors to guarantee a seamless and effective implementation. One of the primary considerations revolves around the compatibility between the temperature transmitters and the designated control system. Selecting transmitters that align with the communication protocols and interfaces supported by the control system is paramount. This is to ensure interoperability and smooth data exchange.

Moreover, the selection process should also prioritize factors such as the accuracy, reliability, and environmental adaptability of the temperature transmitters. Opting for transmitters with high precision and robust performance capabilities is crucial to maintaining the integrity of temperature data and enabling precise control actions within the system. Additionally, assessing the transmitters' resilience in varying environmental conditions is fundamental to guarantee consistent and dependable operation across diverse operational settings.

Furthermore, when contemplating the integration of temperature transmitters with control systems, it is imperative to conduct a comprehensive assessment of the scalability and expandability of the integrated solution. Anticipating future operational needs and potential expansion requirements ensures that the integrated system can accommodate evolving demands, technological advancements, and business growth without necessitating substantial reconfigurations or overhauls.

Step-by-Step Guide to Integrating Temperature Transmitters with Control Systems

Integrating Yokogawa Temperature Transmitter Yta610 with control systems requires careful planning and execution. Below is a step-by-step guide to help streamline the integration process:

-

Assess System Requirements: Begin by assessing the temperature monitoring and control requirements of your industrial process. Identify the specific parameters that need to be monitored and controlled, as well as any regulatory or compliance requirements.

-

Select Suitable Temperature Transmitters: Based on your system requirements, choose temperature transmitters that are compatible with your control system and capable of accurately measuring the desired parameters.

-

Install and Configure Transmitters: Install the selected temperature transmitters in the appropriate locations within your industrial process. Ensure proper wiring and configuration according to the manufacturer's guidelines.

-

Integrate with Control System: Connect the temperature transmitters to the control system using the designated communication protocols and interfaces. Configure the control system to receive and interpret temperature data from the transmitters.

-

Test and Validate: Once the integration is complete, conduct thorough testing to ensure that the temperature monitoring and control functions are working as intended. Validate the accuracy and reliability of the integrated system under various operating conditions.

Real-world Applications and Case Studies of Integrated Systems

The integration of temperature transmitters with control systems finds wide-ranging applications across various industries. In the pharmaceutical industry, precise temperature control is critical for maintaining the efficacy and stability of drugs during storage and transportation. By integrating temperature transmitters with control systems, pharmaceutical companies can ensure compliance with regulatory requirements and safeguard product quality.

In the manufacturing sector, integrated systems enable efficient monitoring and control of temperature-sensitive processes such as heat treatment, curing, and drying. By closely monitoring and regulating temperature conditions, manufacturers can optimize production processes, reduce energy consumption, and minimize waste.

Contact us for Professional Solutions

For professional solutions and expert guidance on integrating Yokogawa Temperature Transmitter Yta610 with control systems, look no further. As a leading manufacturing supplier with a GMP factory, large inventory, and complete certificates, we are committed to providing high-quality products and superior customer service. Whether you require OEM support, fast delivery, or comprehensive testing, we have you covered. Contact us at lm@zyyinstrument.com to learn more and explore how we can collaborate to optimize your industrial processes.

References:

- "Temperature Transmitters: Selection, Application, and Installation Guide" - Emerson

- "Fundamentals of Industrial Automation and Control" - ISA

- "Integration of Sensors and Actuators with Control Systems" - Springer

- "Practical Guide to Temperature Measurement and Control" - Omega Engineering

- "Case Studies in Industrial Automation" - Wiley-IEEE Press

YOU MAY LIKE

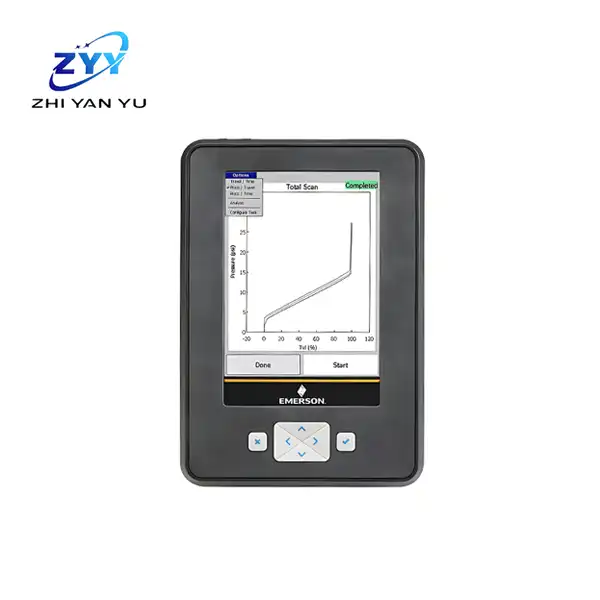

AMS Trex device communicator

Rosemount 3051GP pressure transmitter

Yokogawa EJX310A high-performance absolute pressure transmitter

Henghe EJX510A direct-mounted absolute pressure transmitter

Output 4~20mA DC current signal.

Fast response, remote setup and monitoring.

Diagnostic functions: high/low pressure alarm output.

Multi-sensing technology detects anomalies. FF fieldbus type is available.

TÜV certified and meets SIL 2 safety requirements.

Yokogawa EJX130A high static pressure differential pressure transmitter