- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Pressure transmitter selection for high-pressure applications

2024-07-19 18:17:18

Pressure transmitter selection for high-pressure applications

1. Understanding the Importance of Pressure Transmitters

Pressure transmitters assume a significant part in different ventures by precisely estimating and observing pressure levels in different applications. Among these, the Rosemount 3051CA pressure transmitter stands apart as a prominent model famous for its unwavering quality, accuracy, and flexibility. Understanding the significance of pressure transmitters, especially the Rosemount 3051CA, is fundamental for valuing their effect on modern cycles and frameworks.

At the center of its importance, the Rosemount 3051CA pressure transmitter empowers ongoing estimation and control of pressure, working with ideal activity and proficiency across a great many applications. By giving exact pressure information, it considers the exact guideline of cycles, guaranteeing quality, security, and consistence with industry principles.

One of the vital advantages of the Rosemount 3051CA is its cutting edge innovation and powerful development, which empowers it to endure cruel natural circumstances, outrageous temperatures, and destructive substances regularly experienced in modern settings. This solidness and strength add to its life span and unwavering quality, diminishing upkeep necessities and limiting personal time.

In addition, the Rosemount 3051CA offers improved availability and correspondence capacities, empowering consistent mix with control frameworks and information obtaining platforms. This empowers remote observing, diagnostics, and prescient upkeep, enabling administrators to proactively address issues and improve performance.

In enterprises like oil and gas, compound handling, drugs, and water treatment, where exact pressure control is basic for wellbeing, quality, and proficiency, the Rosemount 3051CA assumes an irreplaceable part. It guarantees the trustworthiness of cycles, works with consistence with administrative necessities, and improves generally speaking functional performance.

Moreover, the Rosemount 3051CA adds to cost reserve funds and asset enhancement by limiting waste, lessening energy utilization, and further developing cycle productivity. Its capacity to precisely quantify pressure across a great many working circumstances empowers administrators to recognize open doors for streamlining and productivity enhancements.

All in all, pressure transmitters, exemplified by the Rosemount 3051CA, are basic parts of modern cycles, empowering exact pressure estimation, control, and checking. Their dependability, sturdiness, and high level elements make them key apparatuses for guaranteeing security, quality, and proficiency in different applications, at last adding to the general achievement and manageability of modern tasks.

2. Factors to Consider in High-Pressure Environments

In high-pressure conditions, a few basic variables should be painstakingly considered to guarantee the dependable and safe activity of gear and cycles. These elements are especially applicable in businesses like oil and gas, synthetic handling, aviation, and assembling, where high-pressure conditions are normal. One fundamental thought is the selection of proper instrumentation, like pressure transmitters, equipped for enduring and precisely estimating high-pressure levels.

The Rosemount 3051CA pressure transmitter is a remarkable illustration of instrumentation planned explicitly for high-pressure applications. While assessing pressure estimation answers for high-pressure conditions, a few key variables ought to be considered:

- Pressure Rating: The pressure transmitter should have an adequate pressure rating to endure the most extreme working pressure inside the climate. The Rosemount 3051CA offers high-pressure evaluations, making it appropriate for use in requesting applications where pressures can surpass ordinary cutoff points.

- Material Similarity: Parts presented to high-pressure liquids should be built from materials that are viable with the interaction media to forestall erosion, debasement, or tainting. The Rosemount 3051CA is accessible with different wetted materials to guarantee similarity with a large number of cycle liquids and conditions.

- Precision and Unwavering quality: Exact pressure estimation is significant for keeping up with process productivity, wellbeing, and administrative consistence in high-pressure conditions. The Rosemount 3051CA highlights progressed sensor innovation and adjustment methodology to convey exact and dependable estimations significantly under outrageous tension circumstances.

- Ecological Circumstances: High-pressure conditions frequently harmonize with testing natural circumstances, like high temperatures, destructive environments, or unsafe regions. The pressure transmitter ought to be intended to endure these circumstances without compromising performance or wellbeing. The Rosemount 3051CA offers tough development and choices for perilous region confirmations, making it reasonable for use in brutal working conditions.

- Establishment and Upkeep: Simplicity of establishment, alignment, and support are fundamental contemplations in high-pressure applications, where personal time should be limited, and wellbeing conventions stuck to. The Rosemount 3051CA is intended for basic establishment and dispatching, with highlights, for example, simple to-get to terminal blocks and indicative capacities for proactive support.

- Incorporation and Similarity: Similarity with existing control frameworks, correspondence conventions, and information connection points is urgent for consistent coordination of pressure estimation instrumentation into the more extensive interaction foundation. The Rosemount 3051CA backings different correspondence conventions and can be handily coordinated into control and observing frameworks.

Wellbeing and Consistence: High-pressure conditions present intrinsic dangers, expecting adherence to rigid security guidelines and administrative necessities. The pressure transmitter ought to agree with industry norms and affirmations to guarantee the wellbeing of faculty, gear, and the climate. The Rosemount 3051CA satisfies applicable industry guidelines and confirmations, offering genuine serenity with regards to somewhere safe and consistence.

Via cautiously assessing these elements and choosing fitting instrumentation, for example, the Rosemount 3051CA, associations can really deal with the difficulties related with high-pressure conditions, guaranteeing ideal performance, wellbeing, and dependability in basic modern cycles.

3. The Role of Technology in Pressure Transmitter Selection

Innovation assumes a significant part in the selection of pressure transmitters, with progressions empowering upgraded performance, dependability, and usefulness. The Rosemount 3051CA pressure transmitter represents the crossing point of state of the art innovation and instrumentation configuration, offering a scope of elements that take care of different modern applications.

One of the essential ways innovation impacts pressure transmitter selection is through sensor development. High level sensor innovations, for example, silicon strain checks and slender film piezoresistive components, empower the exact and exact estimation of pressure across many working circumstances. The Rosemount 3051CA uses cutting edge sensor innovation to convey highly exact and repeatable pressure estimations, even in requesting high-pressure conditions.

Furthermore, mechanical headways have prompted the advancement of insightful pressure transmitters outfitted with computerized correspondence capacities. The joining of conventions like HART, Establishment Fieldbus, and PROFIBUS empowers consistent network with control frameworks, working with remote checking, diagnostics, and control. The Rosemount 3051CA highlights computerized correspondence choices, considering simple combination into present day modern computerization models.

Another huge mechanical viewpoint affecting pressure transmitter selection is symptomatic usefulness. High level analytic calculations implanted inside the transmitter empower proactive observing of gadget wellbeing and performance, working with prescient upkeep and investigating. The Rosemount 3051CA utilizes demonstrative abilities to identify issues, for example, sensor float, overpressure occasions, and sign irregularities, engaging clients to resolve likely issues before they heighten.

Besides, innovation assumes a vital part in improving the power and dependability of pressure transmitters. Ruggedized development, airtight fixing, and high level materials guarantee toughness and life span, even in cruel working conditions portrayed by outrageous temperatures, vibrations, or destructive substances. The Rosemount 3051CA flaunts a rough plan designed to endure testing conditions, making it reasonable for many modern applications.

In addition, headways in adjustment strategies and advanced pay calculations add to further developed exactness and security over the whole functional life expectancy of the pressure transmitter. Robotized alignment methodology smooth out appointing and support errands, lessening margin time and functional expenses. The Rosemount 3051CA uses refined alignment techniques and temperature pay calculations to convey steady performance and limit estimation mistakes.

4. Considerations for Safety and Compliance

In industries where safety is paramount, such as oil and gas exploration, petrochemical refining, and aerospace manufacturing, selecting pressure transmitters that meet stringent safety standards and regulatory requirements is critical. Devices certified for use in hazardous or explosive atmospheres, such as those with ATEX or IECEx certifications, provide assurance that they have undergone rigorous testing and comply with industry-specific safety guidelines.

Furthermore, pressure transmitters used in high-pressure applications must undergo thorough testing and validation to ensure their performance and reliability under extreme conditions. Manufacturers often conduct extensive testing, including pressure cycling, temperature stability, and environmental testing, to verify the durability and accuracy of their products. By choosing pressure transmitters from reputable manufacturers with a proven track record of quality and reliability, users can minimize the risk of equipment failure and downtime.

5. The Future of Pressure Transmitter Technology

As Rosemount 3051CA to evolve and demand for high-pressure applications grows, the development of innovative pressure transmitter technologies is expected to accelerate. Advancements in materials science, sensor design, and digital electronics will drive the evolution of pressure sensing devices, enabling greater accuracy, reliability, and functionality.

One promising area of research is the integration of pressure transmitters with advanced data analytics and artificial intelligence algorithms to enable predictive maintenance and process optimization. By analyzing real-time pressure data and identifying trends and anomalies, these intelligent systems can help operators anticipate potential issues before they occur, thereby reducing downtime and improving overall efficiency.

In conclusion, selecting the right pressure transmitter for high-pressure applications is essential for ensuring safety, efficiency, and reliability in industrial processes. By considering factors such as pressure range, media compatibility, technology features, safety, and compliance, users can make informed decisions and choose transmitters that meet their specific requirements. With ongoing advancements in technology and a commitment to quality and innovation, the future of pressure transmitter technology looks promising, paving the way for safer, more efficient, and more reliable industrial operations.

Contact us: For professional manufacturing solutions, contact us at lm@zyyinstrument.com. As a GMP factory with a large inventory and complete certificates, we support OEM requests, offer fast delivery with tight packaging, and provide testing support. Join hands with us to enhance your industrial processes.

References:

- "Pressure Transmitter Selection Guide", Emerson Automation Solutions.

- "Pressure Measurement Solutions for High-Pressure Environments", WIKA.

- "Wireless Pressure Transmitter Technology", Yokogawa Electric Corporation.

- "Pressure Transmitter Certification and Compliance", Endress+Hauser.

- "Future Trends in Pressure Transmitter Technology", Market Research Future.

YOU MAY LIKE

Rosemount™ 3144P temperature transmitter

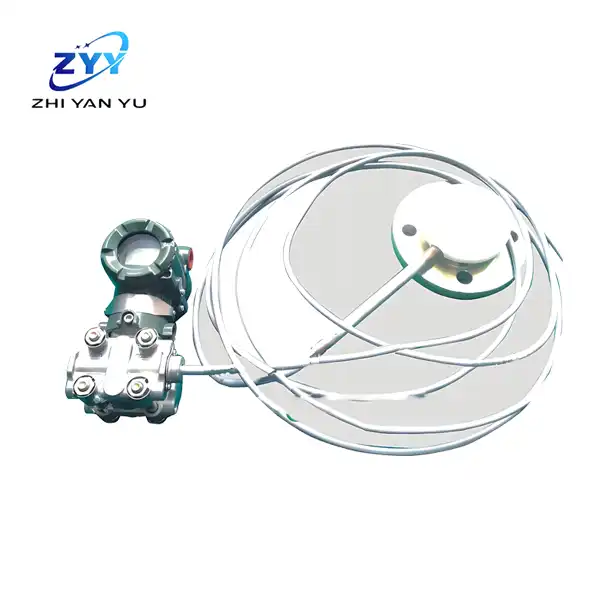

Yokogawa EJX438A diaphragm sealed pressure transmitter

Yokogawa EJA118E diaphragm sealed differential pressure transmitter

Yokogawa EJX130A high static pressure differential pressure transmitter

Fisher FieldVue DVC6010 Valve Positioner