- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Temperature transmitter maintenance and preventive care

2024-06-11 17:05:40

Temperature Transmitter Maintenance and Preventive Care

In the realm of industrial processes, temperature transmitters play a pivotal role in ensuring operational efficiency and safety. These devices, responsible for monitoring and transmitting temperature data, are integral components across various sectors, including manufacturing, energy, and healthcare. However, like any other equipment, temperature transmitters require regular maintenance and preventive care to uphold their functionality and longevity. In this comprehensive guide, I will delve into the essential practices for Rosemount 214c Temperature Sensor maintenance and offer insights into preventive measures to enhance their performance and reliability.

Understanding Temperature Transmitters

Before delving into maintenance procedures, it's crucial to grasp the fundamentals of temperature transmitters. Temperature transmitters are electronic devices used to measure and transmit temperature data accurately and reliably in various industrial processes and applications. They typically consist of a temperature sensor, signal conditioning circuitry, and a communication interface.

The temperature sensor, often a thermocouple or resistance temperature detector (RTD), detects changes in temperature and converts them into electrical signals. These signals are then processed and conditioned by the circuitry within the transmitter to ensure accuracy and stability.

The correspondence interface permits the transmitter to send the temperature information to a control framework or show gadget, normally utilizing normalized conventions, for example, 4-20 Mama simple signs or computerized conventions like HART or Modbus. These gadgets act as imperative instruments for estimating temperature in different modern cycles. Whether it's checking the temperature of compound responses in an assembling plant or managing the intensity in a heater, temperature transmitters give ongoing information pivotal to functional navigation.

Importance of Regular Maintenance

Proactive maintenance is the cornerstone of ensuring optimal performance and longevity of rosemount 214c rtd temperature sensor. By adhering to a scheduled maintenance regimen, potential issues can be identified and rectified before they escalate into costly breakdowns or failures. Moreover, regular maintenance helps in preserving accuracy and reliability, thereby fostering a safe and efficient working environment. Regular maintenance is essential for ensuring the efficient and safe operation of various systems, equipment, and assets across industries. By conducting scheduled inspections, servicing, and repairs, organizations can proactively identify and address potential issues before they escalate into costly failures or safety hazards.

Upkeep assists with delaying the life expectancy of gear and apparatus, diminishing the requirement for untimely substitutions and related costs. It likewise adds to worked on functional unwavering quality, limiting impromptu personal time and interruptions to creation processes. Also, standard support can upgrade security by distinguishing and correcting possible risks, subsequently safeguarding the prosperity of workers and the general climate.

Moreover, legitimate support can improve energy proficiency and execution, prompting cost investment funds and practical tasks. It likewise supports keeping up with consistence with administrative prerequisites and industry norms, guaranteeing that offices and hardware meet fundamental rules for quality, security, and natural obligation.

Key Maintenance Procedures

-

Calibration and Testing: Regular calibration of Rosemount 214c Temperature Sensor is imperative to maintain accuracy. Calibration ensures that the device provides precise temperature readings, thereby preventing errors that could compromise process control and quality. Additionally, periodic testing helps in validating the performance of temperature transmitters under varying operating conditions.

-

Inspection of Components: Conducting visual inspections of temperature transmitters is essential to identify any signs of wear, corrosion, or damage. Inspecting components such as sensors, wiring, and enclosures allows for early detection of potential issues, enabling timely interventions to prevent malfunctions or breakdowns.

-

Cleaning and Lubrication: Dust, debris, and contaminants can accumulate on the surface of temperature transmitters, hindering their performance. Regular cleaning using appropriate cleaning agents helps in maintaining optimal functionality. Additionally, lubrication of moving parts ensures smooth operation and prevents premature wear and tear.

-

Environmental Considerations: Temperature transmitters are often exposed to harsh environmental conditions, including extreme temperatures, humidity, and corrosive substances. Implementing protective measures such as weatherproof enclosures and corrosion-resistant coatings safeguards the integrity of temperature transmitters, prolonging their service life.

-

Software Updates and Upgrades: In today's digital age, many temperature transmitters are equipped with advanced software for data analysis and communication. Keeping the software up to date with the latest patches and upgrades is essential to address security vulnerabilities and enhance performance. Regular software updates also enable compatibility with evolving technologies and protocols.

Preventive Measures for Long-Term Reliability

In addition to routine maintenance, adopting preventive measures can significantly contribute to the long-term reliability of rosemount 214c rtd temperature sensor. By implementing the following practices, operators can mitigate potential risks and extend the lifespan of their equipment:

-

Training and Education: Providing comprehensive training to personnel responsible for temperature transmitter operation and maintenance is crucial. Equipping operators with the necessary knowledge and skills empowers them to identify issues proactively and implement appropriate corrective measures.

-

Spare Parts Management: Maintaining an inventory of critical spare parts ensures prompt replacement in the event of component failure. By stocking essential components such as sensors, connectors, and circuit boards, downtime can be minimized, thereby optimizing operational efficiency.

-

Documentation and Record-Keeping: Maintaining detailed records of maintenance activities, calibration schedules, and equipment specifications is essential for traceability and compliance. Documentation facilitates trend analysis, enabling data-driven decision-making and continuous improvement initiatives.

-

Risk Assessment and Mitigation: Conducting periodic risk assessments helps in identifying potential hazards and vulnerabilities associated with temperature transmitter operation. Implementing mitigation strategies such as redundancy, isolation, and protective barriers enhances system resilience and minimizes the likelihood of failures.

-

Vendor Support and Collaboration: Establishing a collaborative partnership with reputable vendors and suppliers ensures access to technical support, expertise, and resources. Leveraging vendor support for troubleshooting, training, and product updates enhances the overall reliability and performance of temperature transmitters.

Conclusion

In conclusion, Rosemount 214c Temperature Sensor maintenance and preventive care are paramount for ensuring operational efficiency, reliability, and safety in industrial processes. By adhering to a structured maintenance regimen and implementing proactive measures, operators can mitigate risks, minimize downtime, and prolong the lifespan of their equipment. Remember, investing in maintenance today translates into savings and productivity gains tomorrow.

Contact Us

For professional manufacturing solutions, contact us at lm@zyyinstrument.com. As a GMP factory with a large inventory and complete certificates, we offer OEM support, fast delivery, and comprehensive testing services. Partner with us and experience unparalleled reliability and efficiency in your industrial operations.

References

- "Temperature Transmitter Maintenance Best Practices" - International Society of Automation

- "Preventive Maintenance Strategies for Industrial Equipment" - Maintenance Technology Magazine

- "Importance of Calibration in Industrial Process Control" - Control Engineering Magazine

- "Environmental Considerations for Industrial Instrumentation" - Environmental Science & Technology Journal

- "Risk Assessment and Management in Industrial Facilities" - Occupational Safety and Health Administration

YOU MAY LIKE

Honeywell St800 Pressure Transmitter

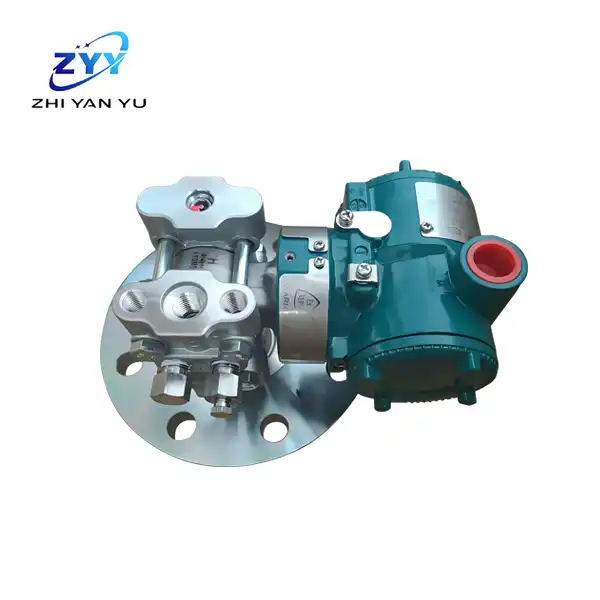

Rosemount 8705 Flange type electromagnetic flowmeter sensor

Rosemount™ 248 rail-mounted temperature transmitter

Yokogawa EJX120A differential pressure transmitter

Yokogawa EJA210E flange-mounted differential pressure transmitter

E+H PMD75

Measurement: Operates by comparing pressures at these ports.

Use: Suitable for differential pressure applications.